STC values and performance of PV panels

Renewable energy sources

The sun is an important source of renewable energy with a quite low environmental impact. Its main problem is that as a source of energy it is not available everywhere or all of the time. In parts of the world where the sun is plentiful it can make a reasonable impact in its role of a non-dispatchable supply. This means while its output is predictable in the long term, it is not on an hourly or even daily basis.

Energy from the sun can be used in two ways: as heat source for thermal turbines, or directly through use of photovoltaic cells. As a heat source, it works in a very similar way to any thermal plant. Photovoltaic cells are a type of semiconductor that creates direct current when illuminated. The current fluctuates with intensity of light.

Each individual PV cell produces too low a voltage to be useful, therefore they are connected in series to form a string. Multiple strings are then connected in parallel to achieve desired power and create a panel with useful voltage and power output. Panels are further collected into arrays. Organisation of collecting the power depends on the location, but often power is collected from each array separately before leading it to the inverter.

Measurements

Photovoltaic system is composed of solar cell arrays and its concomitant support system that contains supportive structures, wiring, overvoltage protection, an inverter to change produced DC to more commonly used AC voltage, optionally a battery system, charge controller, a metering solution for feeding power to the grid, maximum power point tracker, and other equipment for improving efficiency.

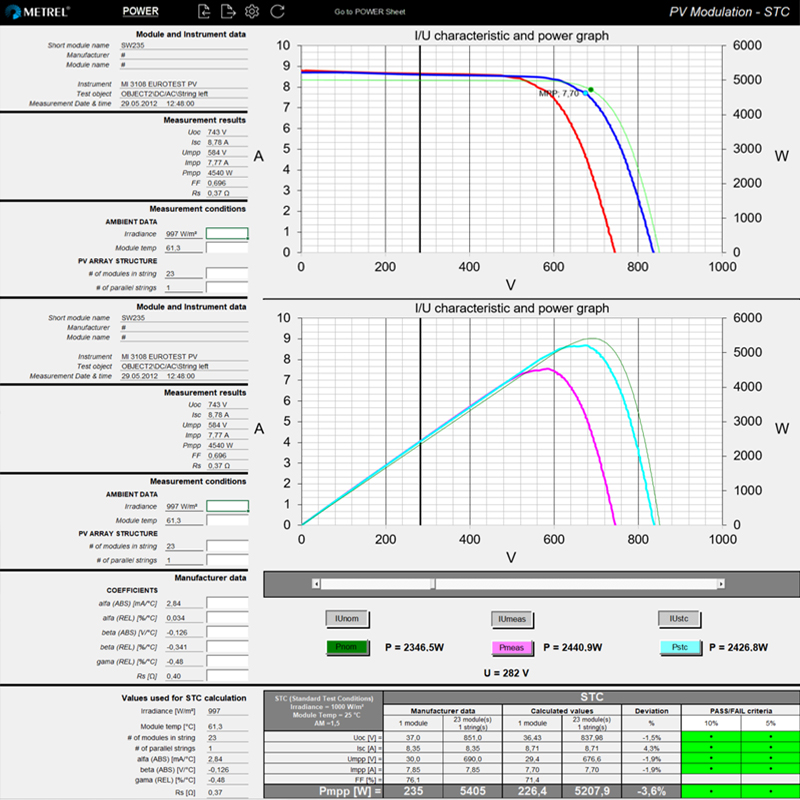

Photovoltaic systems need little maintenance and do not have a prescribed period for testing. It is much more likely they will slowly become ineffective than dangerous, but as with any high voltage electrical installation it is better to be on the safe side. Particularly heat in case of poor ventilation of the arrays can be an issue: it causes all materials to age faster. Overheated and weakened insulation on wires that carry high voltage is a fire hazard. UV rays and moisture can have a similar effect. The materials must be chosen accordingly, and wires appropriately protected. Measurements of performance must be compared to the extrapolated performance of the panel at the STC (standard test conditions) to show any deterioration. Often the expression ‘STC’ refers to the actual performance of the panel at temperature 25°C, irradiance of 1000 W/M2 and air mass AM1.5.

It is desirable to keep the whole panel well irradiated. Any shaded cell fails to create voltage or in case of design failure even sucks voltage from neighbouring cells. Efficiency can be boosted by keeping the panels clean, with tracking systems, or active cooling. All these techniques add to required maintenance. The optimal solution is a simple fixed tilt for the sun to be perpendicular at noon and to help the rainwater to clean the panel.

Inverters have to take the DC input from the solar panels and transform it to a sine wave, with frequency synchronized to the grid frequency and an amplitude limited to the grid value. Disconnection from the grid in case of an outage, to prevent islanding, is also managed in the inverter. Grid-connected inverters will use a proprietary algorithm to extract maximum power from the cells, called maximum power point tracking (MPPT). It comprises of digital sampling of the solar output and applying optimal resistance to the output. Typically, inverters achieve 98% power efficiency.

MI 3109 is a photovoltaic tester that can automatically check performance and safety parameters of the solar array. The photovoltaic part covers requirements of the standard IEC/EN 62446, I-V characteristic, STC values as required by IEC 61829 and functionality of the inverter. Power measurements require additional use of a PQA instrument that can be connected to MI 3109. These measurements give indication of panel health, its efficiency at the prevailing conditions, and can (depending on the connections) locate faults. You are advised to use safety probes for testing the high-voltage parts.

Measurements were done on a local primary school building that supplements its consumption with the panels. First measurement must always be equipotential bonding for each array – without a connection in place, the array is not functional and any other measurements don’t make sense. Once state of connection is established, the A 1378 Remote unit that will monitor irradiance and temperature will be installed. The reference cell must be carefully set up to the same angle as arrays and the temperature probe firmly attached.

Measurements were done on a sunny day in May, with irradiance reaching 889 W/m2 and array temperature at stable 73,8°C. The temperature is uncommonly high – the installation on low supports on the roof that leaves little air below them, and a small angle of installation, caused hot air to get caught beneath them.

Insulation was measured next. Each array was disconnected from the inverter and insulation measured for the whole system of wires and solar panels. We expected the results to show deterioration due to heat exposure, but the value was similar to the measurement at installation – 71,7 MΩ.

The I/V curve measurements with MI 3109 were done for each string separately. To calculate the STC values of the arrays, their specifications need to be input. The Android app EurolinkPV enables uploading the information from a database or makes the input easier in case of modules not yet in the base.

Measurements of performance included the I/V curve with open clamp voltage, short circuit current and maximum power point. Results were collected into the Android PV application for processing and graphic presentation.

Measurements showed poor performance of the modules. Power output was limited to about 73% of the STC value. Heat was clearly the main issue. The best long-term would be reinstallation to lift the panels higher above the roof and change their angle. Another possible approach aims to use the excess heat. Water is used to simultaneously cool the panels and add to water heating.