Lightning protection testing in wind plants

Renewable energy sources

The use of wind as power source is ancient. The technology matured and today it no longer provides mechanical power but generates electricity. The wind drives giant blades up to 90m long to rotate a shaft that is connected to a turbine that can generate megawatts of power. They must stand a distance away from other tall object to be able to catch as much wind as possible. Their height and preferred location make them giant lightning rods.

There are two options for design of a wind turbine: the more common type with horizontal axis and vertical blades that provides higher efficiency, and the type with vertical axis, that provides higher reliability and easier maintenance with access to vital parts at ground level. The latter is more commonly used for small scale or private operations, which keeps is smaller and less lightning prone.

Design with horizontal axis puts the main components, rotor with blades and the generator, high in the air. A sensor array turns the blades towards the wind. It is common to use a gearbox, a continuously variable transmission or adjustable speed drive, to change the slow rotation of the blades to higher speeds more suited to driving a generator than using a generator suited to slower speeds. Commercial variants usually have a rotor with three blades, which offers low torque ripple and good reliability.

Vertical axis designs are more suited to smaller or private ventures. The rotor does not have to point into the wind to be effective and the shaft can be brought to the ground before entering the generator, easing the maintenance. However, lower energy yield over time is a major drawback, along with some mechanical considerations. This is to some degree alleviated if the turbine is placed on a roof, where it can redirect the wind from the roof and even double the rotation speed.

Measurements

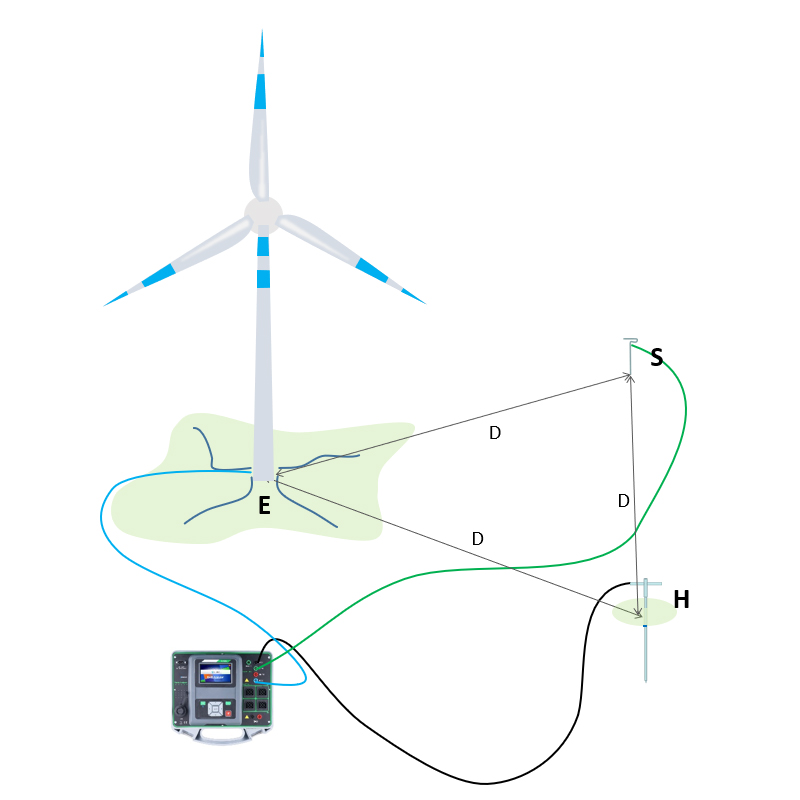

Industrial scale turbines are protected with multiple systems. The basic protection is provided by conductors from the top to the ground. Siutable testing equipment for grounding / earthing testing would be MI 3290 Earth Analyser. The simpliest method is to connect probes in three angle shape.

Sometimes, the metal construction of the tower is used as part of the conductor system. For a more thorough protection a well-coordinated system of surge protectors is necessary as well. Typically, there are at least two in parallel: T1 10/350 and T2 8/20. T1 and T2 are their types. 10/350 and 8/20 mean the shape of overvoltage pulse that they protect against: first number is the rise time in µs, and the second is the fall time. Apart from the pulse shape, the most important specification is the current surge that they can still safely conduct.

Either can be multiplied if deemed necessary. Coordination and installation instructions are prepared by the manufacturer. It depends on the I/U curves and time responses of all the used protectors.

Metrel provides solutions for testing both the surge protection devices and the conductor continuity. Surge protection can be tested using MI 3210 using the programmable timer to set up the voltage ramp. MI 3210 supports voltages up to 10 kV, which enables work in most hight voltage environments, and is high enough to achieve stable measurements on T1 10/350 SPD.

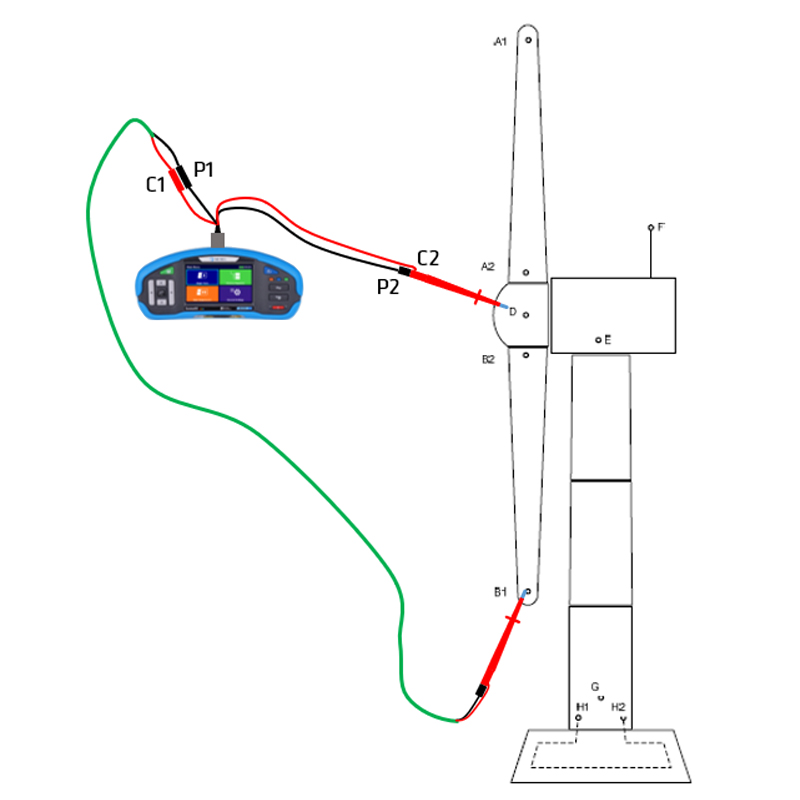

Conductor continuity is best tested using MI 3250 MicroOhm 10A or MI 3288 Eerth Insulation Tester. There are long cables available as accessory to reach the ends of the blades. Some current drop due to resistance of measuring cables is expected. The instruments shall manage testing over 4-wire conection and generate few Amps of testing current when using original 100m long leads – the final value of the current depends on the measured resistance as well. The Kelvin (4-wire) measurement method automatically eliminates the resistance of the test wires from the result.

The necessary measurements are described in the standard IEC 61400-24 2010 Wind turbines – Part 24: Lightning protection. The standard covers all aspects of the protection from design, material properties and installation. Other important standard is IEC 62305 Protection against lightning that contains measurement methods about potential equalisation, earth resistance and step/contact voltages. All of the mentioned are important components of safety against lightning strikes.