Generator stator testing

Renewable energy sources

Today’s electrical wire insulation materials have come a long way since the days of silk and gutta-percha (natural latex), which had to be, paradoxically, kept wet to adhere to the wire and not fall off. They have incomparably better dielectric properties, are cheaper and more durable, and can be manufactured to any shape and form. Nevertheless, they are not immune to degradation by elements such as high and (very) low temperatures, UV radiation, overvoltage, moisture and mechanical forces.

Given the serious consequences of materials’ failure, insulation analysis is one of the basic methods for assessing the proper functioning of virtually any electric machine, appliance, installation or system. Though, requirements, guidelines and standards vastly differ between them. Generators and other (large) rotary electric machines are distinct examples as the insulation is subject to greater stresses than in other applications, particularly high temperatures and mechanical forces. However, it is still susceptible to at first glance mundane elements like moisture, which, if the conditions are right, can wreak havoc and irreparably damage the machine.

Measurements

Moisture, temperature and insulation

Regardless of exact insulating material used, the main effect of moisture is (besides physical degradation of material brought through various chemical processes) the creation of conductive creepage paths that lead to greatly decreased dielectric strength and consequently an increase in likelihood of (dielectric) breakdown. In case of generators, air moisture may be drawn inside the machine through cooling vents or through inconspicuous cracks in those that have a dedicated, closed-loop cooling system (liquid-cooled system).

Temperature fluctuations inside the machine cause the moisture to condense in liquid form and seep in windings’ insulation. If there are no means to dry out the windings or no one checked insulation quality – the machine may have a very short lifespan. But, moisture can enter the machine even when it is not in operation – i.e. in improper storage conditions, exposed to the sun and other damaging environmental influences. Such a machine has to be thoroughly inspected before being put into operation and that was exactly something a Metrel affiliated electrical safety inspector had to do for a 100 kW generator that was suspected to be afflicted with moisture due to storage conditions.

Out of storage, but not yet in operation

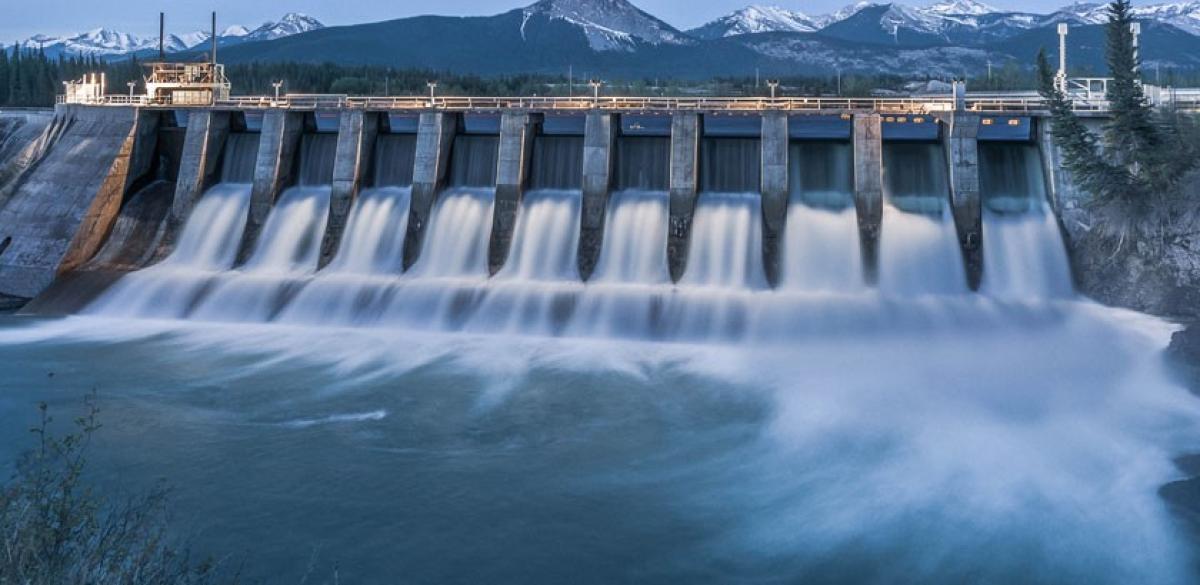

A 100 kW (3-phase, 50 Hz, 400 V / 195 A, 1000 r/min) generator was for about 10 years in use in a micro hydroelectric power plant (Francis turbine), until the plant was dismantled due to issues with the water flow. The generator was then stored in a rather dilapidated warehouse, not far from the former power plant, but near a small pond, together with some other electric machinery, including several large electric motors. The latter were found to have had bad insulation of both the stator (armature) and rotor and had to be repaired, and it was suspected that the generator, which was about to be installed in a new (hydroelectric) power plant, might have similar issues.

Stator and rotor testing

The generator was transported to a repair workshop of a transformer producer. High amounts of electromagnetic interference such as can be found in this and similar environments can be problematic when testing/measuring, but the MI 3210 TeraOhm XA 10kV the inspector used comes with shielded test leads that greatly mitigate this issue. Additionally, it has guard input terminals and the test leads come with appropriate connection leads – elimination of potential leakage currents that are a result of the surface contamination and moisture and that may influence measurement’s accuracy.

Before committing to any insulation resistance measurement/analysis however, more than a passing thought should be given to desired minimum resistance for the given machine/system. Generally speaking, a good rule of thumb is at least 1 MΩ of resistance for every kV. Though, this number (1 MΩ) holds true only at room temperature (20 °C). At higher temperatures the requirements rise very fast – for every 10 °C, the resistance requirement increases for more than 50 % (class B rotary machines). For example, at 40 °C the resistance should be at least 2,5 MΩ for every (rated) kV.

Relationship between moisture and changes in resistance is not as simple and greatly varies for different insulation materials, but can still be comfortably stated that any moisture reduces insulation resistance. Anyway, the inspector connected the generator’s stator and stator windings to the MI 3210 TeraOhm XA 10kV and took three separate measurements for each: time rise method/ polarization index (PI), dielectric absorption ratio (DAR) and dielectric discharge test. Of those three, the best choice for assessing moisture damage to the insulation is the dielectric discharge (DD) test.

The tested object is kept under high voltage for an extended time period, usually between 10 and 30 minutes. The voltage is then turned off and the discharge current measured. The generator’s measured (discharge) currents were, as was initially predicted, very high as was (obviously) the DD result, over 5 (good value is generally under 2).

The generator was consequently overhauled; the rotor was removed and given a thorough cleaning, as was the stator. Both were visually checked for damage and were stored in a heated room with controlled atmosphere to completely dry out. After assembly, the generator was again assessed using the MI 3210 TeraOhm XA 10kV and came out with flying colours – the insulation was deemed good and the generator was put into operation in the new power plant.